we made a Portable cooling jacket for our 3rd year project (integrated design project)

1st approach

Initially, we considered using Baffles to optimize air circulation for heat extraction, but the numerous bends caused friction loss, preventing the duct fan from pushing air effectively to the end of the zigzag path. Rather resulted in unexpected backflow at the inlet. This can be solved by giving filets to the 90 deg bends but still, we were not confident enough that this would even work or not and the probability was in favor of failure. So wasting no more time we swiftly migrated to another plan.

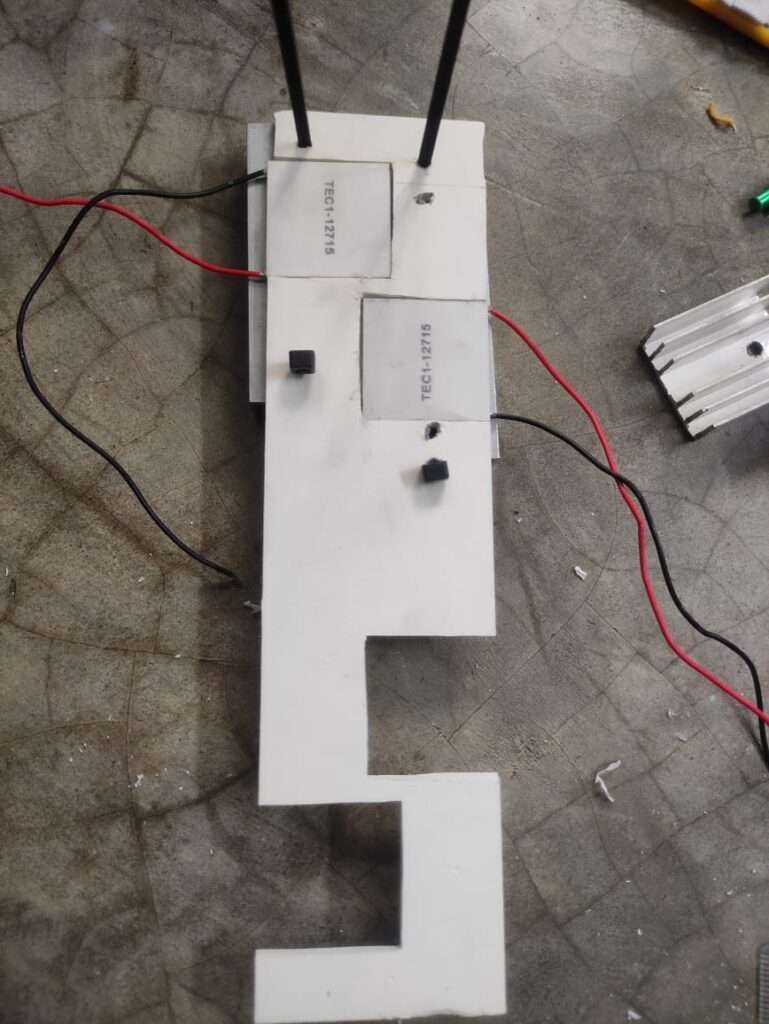

The second plan was eliminating the baffles and making a straight path for the airflow and also place the Peltier close to each other reducing the overall area and increasing the cooling density.

2nd approach

Secondly, we made the same machine but on a smaller scale and increased the cooling density. But the cooling side fan was not able to pass the air all the way through, So another problem arose and again we couldn’t extract the cold.

The problem we observed this time was that the air couldn’t take the coolness from the surface efficiently, maybe because the total surface area of the cold side or the number of fins on the heatsink wasn’t enough or the convection coefficient of air was very low compared to other fluids.

We focused on a hassle-free way to do the job by using air which would have been a great choice if it worked as air is everywhere in the environment so the users needed not to worry about the fluid or any leaks or refilling the fluid etc. We failed again but came up with a totally new plan which was distinct from the previous plans.

3rd approach

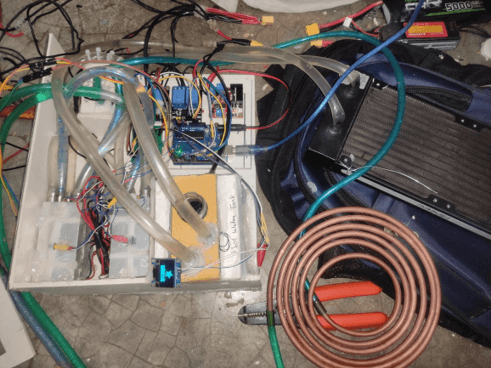

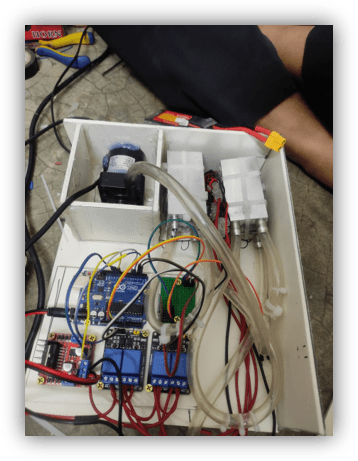

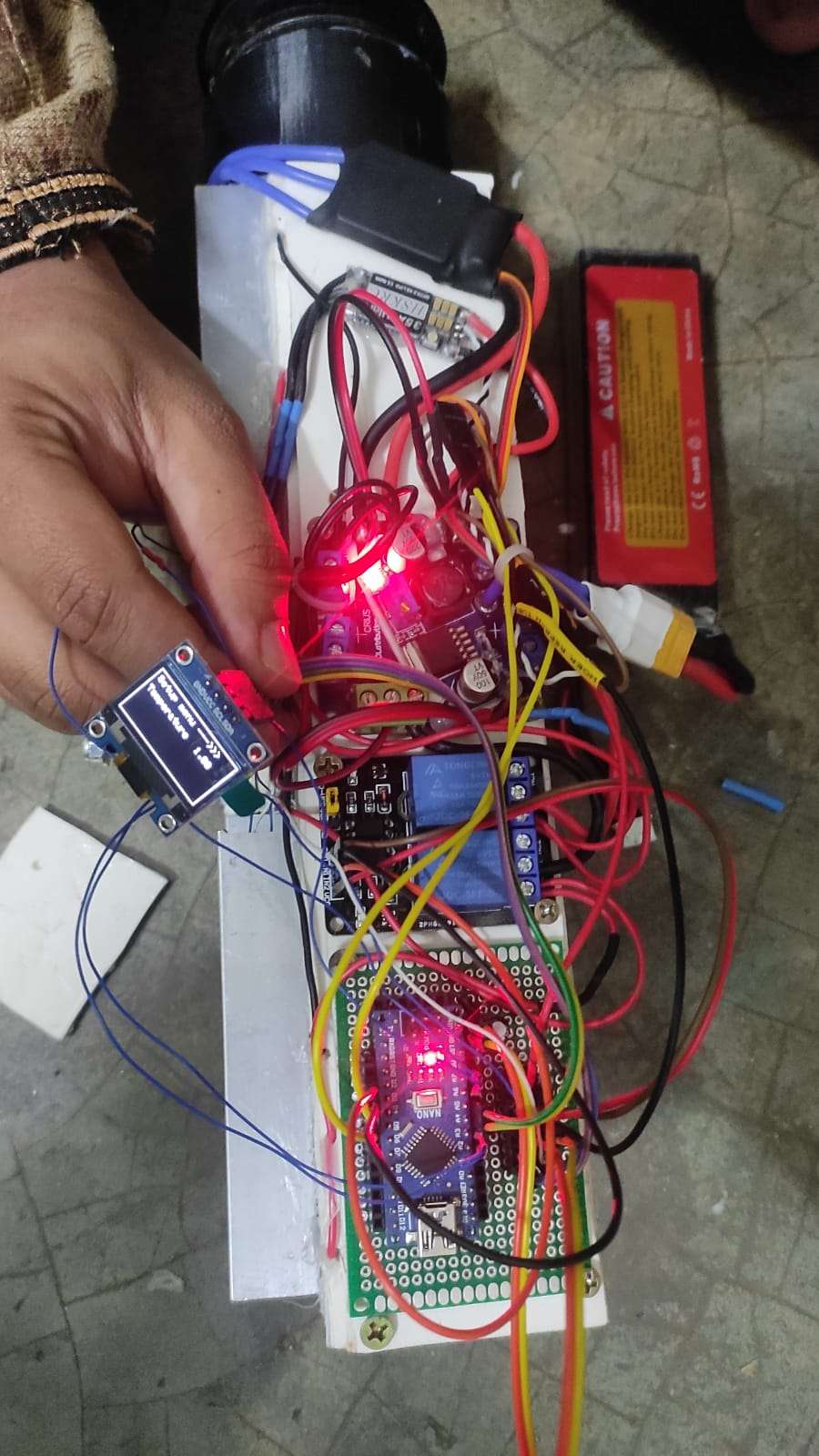

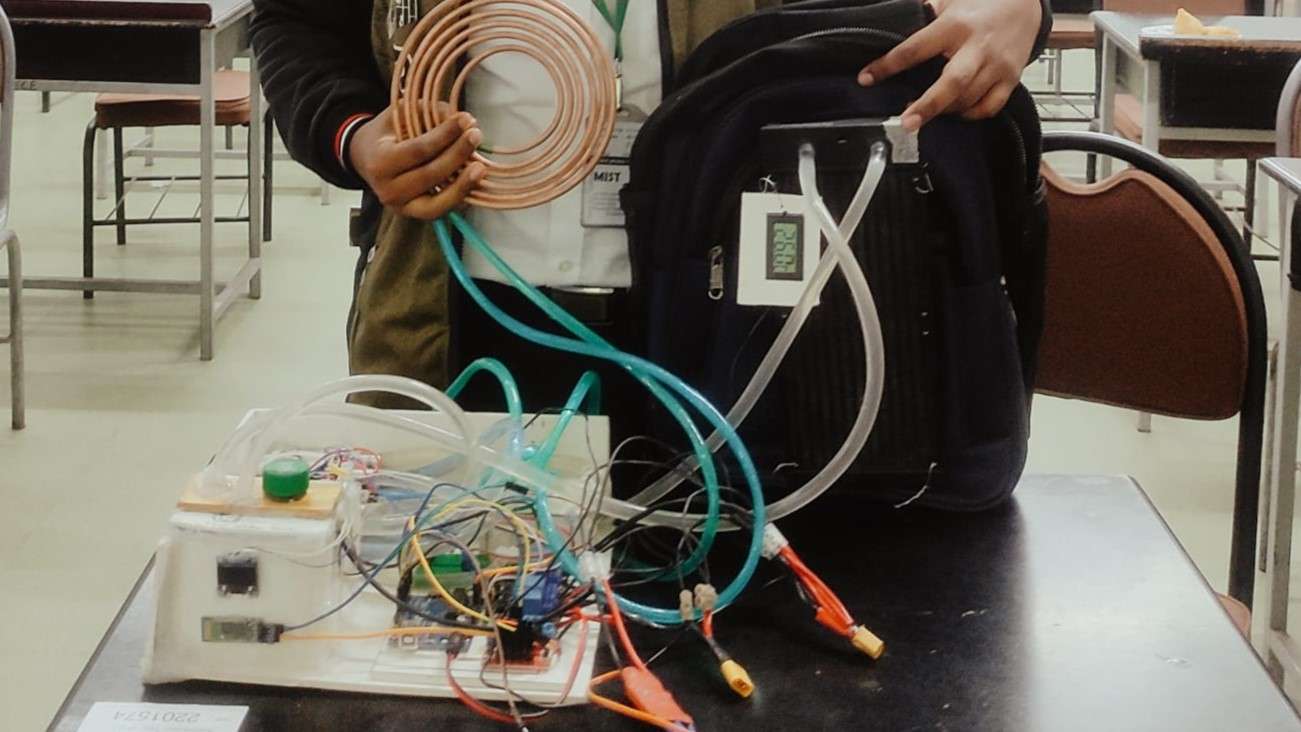

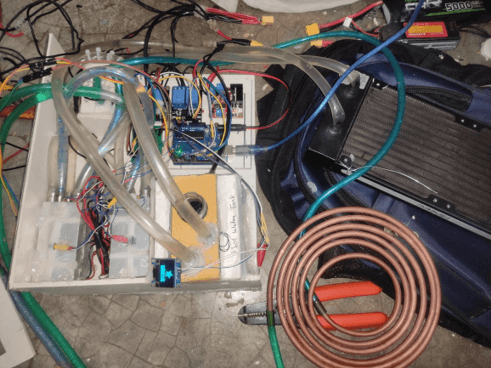

Finally, We designed the project entirely on water cooling. Water is used as both the hot side and the cold side coolant. A mini water radiator is used to cool down the hot water.

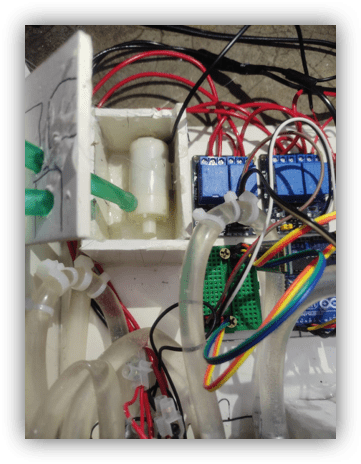

Here Aluminium blocks are used to extract the heat and cold from the Peltiers by circulating the water. Then the water from the hot side Aluminium block is circulated through the radiator using plastic pipes. A submersible pump (12v) is placed inside the reservoir to force the hot side water to flow through the entire system.

Another small submersible pump(6v) is also used in the cold side reservoir to pressurize the water to flow from the reservoir through the Aluminium block, to the copper pipes.

This time We succeeded with our innovation and were able to cool down the system to our desired temperature without using any sort of compressor, condenser, evaporator, or AC power supply. This machine is entirely powered by Lipo batteries and thus fully portable.